由于肤感板,有良好的触觉和视觉效果,已经成为家具和装饰材料行业应用的一个热点。目前肤感效果一般可以由四种加工技术得到:

The good tactile and visual effects of super matte board has become a hot spot in furniture and decorative materials industry. At present, the super matte effect can be generally obtained by four processing technologies:

一、膜压技术Membrane pressure technology

在做好底漆的工件上,辊涂UV面漆,用肤感膜压压平肤感面漆,通过UV光源固化后,把膜揭掉,就得到膜压的肤感产品。

On the work piece with primer, apply UV top coating on roller, press and flatten the top coat with super matte film, and remove the film after curing with UV light source to get the super matte sensitive product with film pressure.

膜压技术,也只能加工平面产品。并且由于肤感膜的微观结构限制,这类产品,肤感的时效性,在一定条件下,会有所限制。目前,在国内的应用,肤感膜都是一次性使用,导致运营成本也偏高。

Membrane pressing technology can only process plane products. And because of the limitation of the micro structure of the super matte sense film, the timeliness of the sense of this kind of products will be limited under certain conditions. At present, in domestic applications, the super matte film is disposable, resulting in high operating costs.

二、涂料技术Coating technology

目前,自干型油漆(PU,水性),都能通过油漆配方,来实现肤感效果。PU肤感漆较早就已经实现;水性肤感漆,国内已经有好几家油漆厂能够提供。

At present, self drying paint (PU, water-based) can achieve super matte feeling effect through paint formula. PU super matte sensitive paint has been realized earlier; water-based super matte paint has been provided by several paint factories in China.

三、准分子灯固化技术 Curing technology of excimer lamp

1、工作原理Principle

来自于德国的IOT公司创造了172纳米的UV固化设备(EXCIMER),并具有独特的性能,堪称UV固化技术的“黑科技”。

IOT company from Germany has created a 172 nm UV curing equipment (EXCIMER) with unique performance, which can be called the "extreme high technology" of UV curing technology

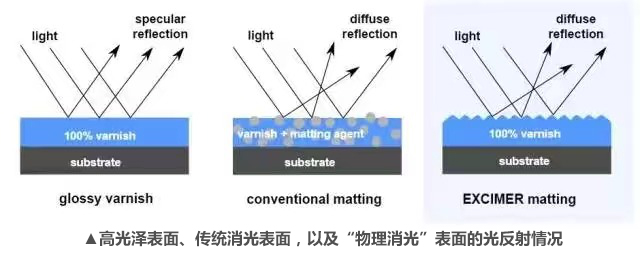

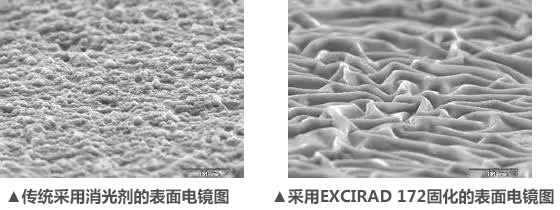

UV涂料配方中的丙烯酸酯双键在吸收172纳米紫外光后,可生成自由基而可以无需光引发剂。同时172纳米UV的穿透深度仅为100到500纳米,因此涂料只有表面极薄的一层被固化。这一薄层的聚合和交联,会发生收缩而形成不光滑的表面,并漂浮在未固化的下层液体上,达到表面哑光的效果。不过这个固化需要在氮气环境下进行,使操作环境的氧气浓度低于100ppm。后续再采用常规UV或者电子束进行完全固化。

After absorbing 172 nm UV light, the acrylate double bond in the formulation of UV coating can generate free radicals without photoinitiator. At the same time, the penetration depth of 172 nm UV is only 100 to 500 nm, so only a very thin layer on the surface of the coating is cured. The polymerization and cross-linking of this thin layer will shrink to form an unsmooth surface, and float on the uncured lower liquid to achieve the surface matte effect. However, this curing needs to be carried out in nitrogen environment, so that the oxygen concentration in the operating environment is lower than 100ppm. After that, conventional UV or electron beam is used for complete curing.

这种消光的方法由于不需要使用消光剂,因此被称为“物理消光”。同时172纳米下表面发生的聚合和交联可提供高的表面硬度及高涂料密度。

This method of extinction is known as "physical extinction" because it does not require the use of a matting agent. At the same time, the polymerization and cross-linking on the lower surface of 172 nm can provide high surface hardness and high coating density.

2、工艺及设备Process and equipment

此种技术目前只能用于平面产品。在做好UV底漆的工件上,辊涂UV肤感面漆,经过LED的深层固化,经过超哑UV设备,再经过常规UV固化设备,就可以得到肤感产品。

At present, this technology can only be used for plane products. On the work pieces with UV primer, apply UV super matte topcoat by roller, deep curing by LED, ultra dumb UV equipment and conventional UV curing equipment to get super matte products.

目前,能提供整套超哑UV设备和技术的,有德国的IOT公司(整机采购价格大约¥100万多一点);能提供核心部件和技术有德国的IST公司(光源及控制系统、氮气控制系统及装置),国内现在能够提供超哑UV设备要不然就是购买IST公司的整机核心部件在国内拼装,要不然就是直接购买IOT公司整机设备。

At present, IOT company in Germany can provide a complete set of super matta UV equipment and Technology (the purchase price of the whole machine is about ¥ 1 million); IST company in Germany can provide core components and Technology (light source and control system, nitrogen control system and device), and now China can provide super matta UV equipment, otherwise, it is to purchase the whole machine core components of IST company for assembly in China, or However, it is to directly purchase IOT complete equipment.

3、特点分析及介绍Characteristic analysis and introduction

①优点:和PU、水性等肤感漆相比,这种肤感产品更耐刮、抗污、防指纹、可修复等。

Advantages: Compared with PU, waterborne and other super matta paints, this skin-sensitive product is more scratch resistant, stain resistant, fingerprint resistant and repairable.

②不足:设备的一次性投资成本高,运营成本较高,只能加工平面产品(如果大板的平整度不够,都会出现次品)。

Disadvantages: The one-time investment cost of equipment is high, the operation cost is high, can only process planar products (if the flatness of large board is not enough, will appear defective).

A. 准分子灯的标准工作寿命正常3000小时,也容易因保养维护不当导致损坏,一支进口光源的价格要5-7万多人民币左右(不同品牌会有差异)。

A. The standard working life of the excimer lamp is normal 3000 hours, and it is also easy to be damaged due to improper maintenance. The price of an imported light source is about 50,000-70,000 RMB (different brands will have differences).

B. 设备运行时,需要大量的高纯氮气。一般正常工作,需要纯度为99.999%氮气20立方/小时。

B. A large amount of high-purity nitrogen is required for the operation of the equipment. Normal operation requires a purity of 99.999% nitrogen of 20 cubic meters per hour.

四、博硕技术路线Richfruits technology route:

博硕致力于提供:低运营成本、可生产异型肤感产品的超哑UV设备,有别于以上技术路线。

Richfruits is committed to providing: low operating cost, ultra dumb UV equipment that can produce special-shaped skin sensing products, different from the above technical route.

欢迎大家交流学习:胡松

Welcome to chat and study:Dr Hu Song

联系方式:0086-13928281959